It used to take almost a month for the owner of It’s The Island Life, a small, Texas-based direct-to-consumer business selling on Shopify, to receive its 3D-printed cookie cutters. Now, it’ll take less than a week.

It’s The Island Life is one of a few brands piloting a new 3D printing program with Voodoo Manufacturing, a Brooklyn-based company that aims to lend its 3D printing production services to small businesses. Today, the company is launching a design app for 3D printing on Shopify, the $17 billion e-commerce platform that has become the go-to e-commerce platform for DTC startups.

Voodoo wants to open up previously pricey 3D printing capabilities for small businesses. Traditional, large 3D-printing corporations employ expensive machines — ranging from $50,000 to $1 million a piece — that pump out millions of products, everything from car parts to baby bottles. Voodoo uses 200 low-end machines that cost less than $5,000 in an effort to provide a production scale without increasing costs.

(Voodoo is not the only app on Shopify: Shapeways, a competitor, recently launched a Shopify app of its own.)

“Our vision is building a digital factory that can produce a large number of the products that people buy in the world,” said Voodoo co-founder and chief product officer Jonathan Schwartz. “It would be impossible for new brands and products to be created and be successful if they needed to invest a lot of time and money in launching large products. That’s something a large company could do, but not a small one.”

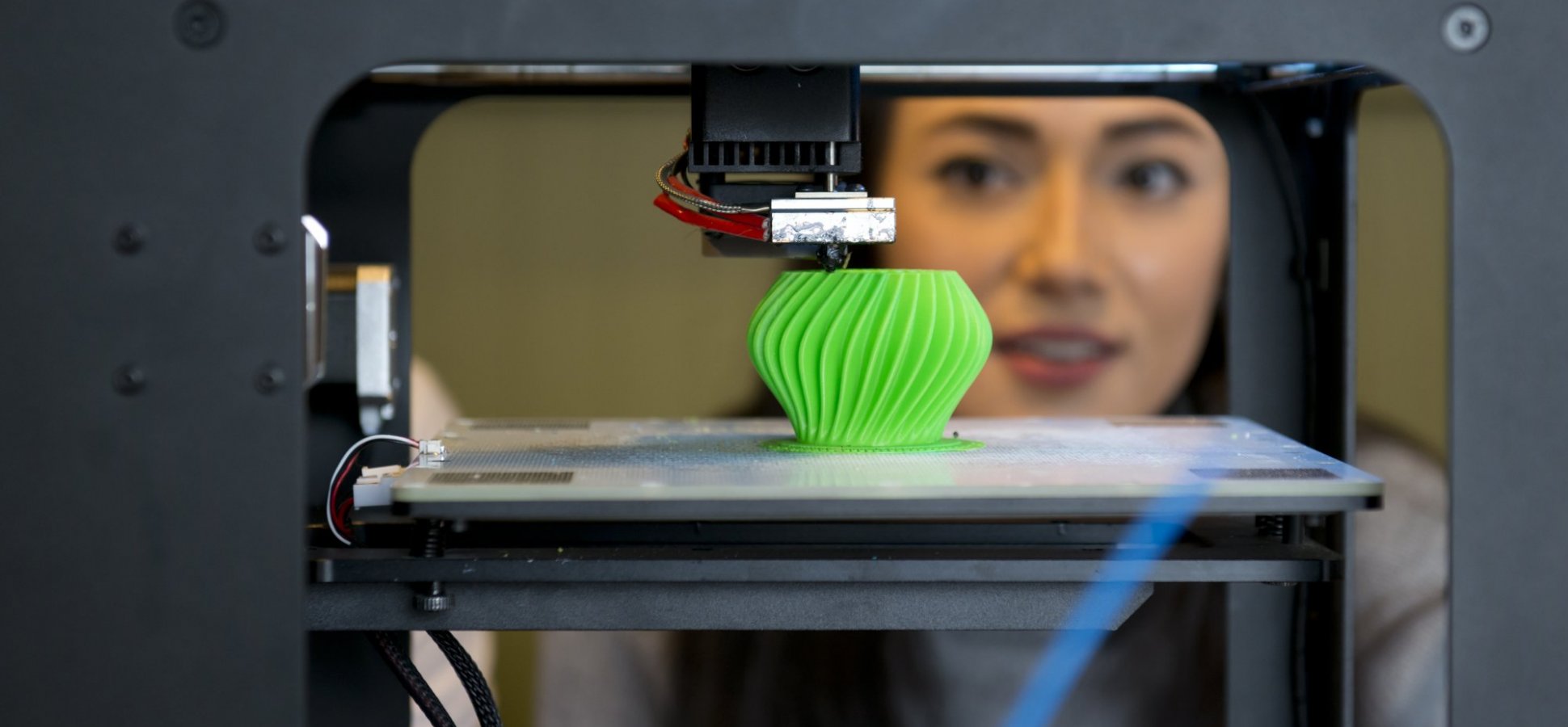

Inside Voodoo’s 2,000-square-foot facility, its printers heat plastic to 230 degrees Celsius and squeeze the material through a hot glue gun-like nozzle, spraying one thin image on a plate at a time, line by line.

The company is looking to capitalize on the growing 3D-printing industry, expected to be worth more than $7 billion by 2024, according to Market Research Engine. Unlike traditional machines, Voodoo’s printers require no molds.

Thanks to the typical upfront cost associated with the manufacturing model, 3D printing has been most often associated with brands with deep pockets. Nike, Adidas and New Balance are all competing to make 3D-printed shoes mainstream, while HP this month announced it was building a 3D printer to help companies produce metal.

Lucy Hutcheson, owner of It’s The Island Life, sells six different cookie cutters designed with the app. The one week it takes Voodoo to turnaround an order compares to the month it used to take other 3D printing companies Hutcheson used before.

The app’s one-week turnaround time outpaces the month it used to take other companies Hutcheson did business with to deliver her products. Many large 3D-printing manufacturers are based in China. At Voodoo, some goods may take up to six hours for a printer to spit out, and the company theoretically could create 200 unique items at a time with each of its 200 printers.

“Our app is going to let people come up and create products that no one else in the world is selling that can be incredibly unique and niche to their customer base, and yet not have to make any investment up-front,” Schwartz said.